Passion for technology.

Generators for Angola, streetcars for Taiwan, paper machines for Holland. Voith is an international technology Group with sophisticated logistics chains. For Alexis von Hoensbroech, Board Member Product and Sales at Lufthansa Cargo, just one reason to get the facts at first hand.

Luanda is growing. Today, more than five million people live in the capital of Angola. 20 years ago there was not even half that number. New factories for cars or clothing are springing up. The demand for electricity for both population and business is rising from day to day. To ensure the lights do not go out in Luanda, Angola is investing heavily in the energy sector. The country is backing water power – and the technology comes from Heidenheim an der Brenz.

Voith – a family-run company with a rich tradition – is equipping a new hydroelectric power station for Angola on the Kwanza River. The technology Group is installing four generators and turbines along with control technology and associated systems for the Cambambe II plant situated around 180 kilometers east of Luanda. Order volume: more than 100 million euros. With the project, Angola will double its installed hydroelectric power output.

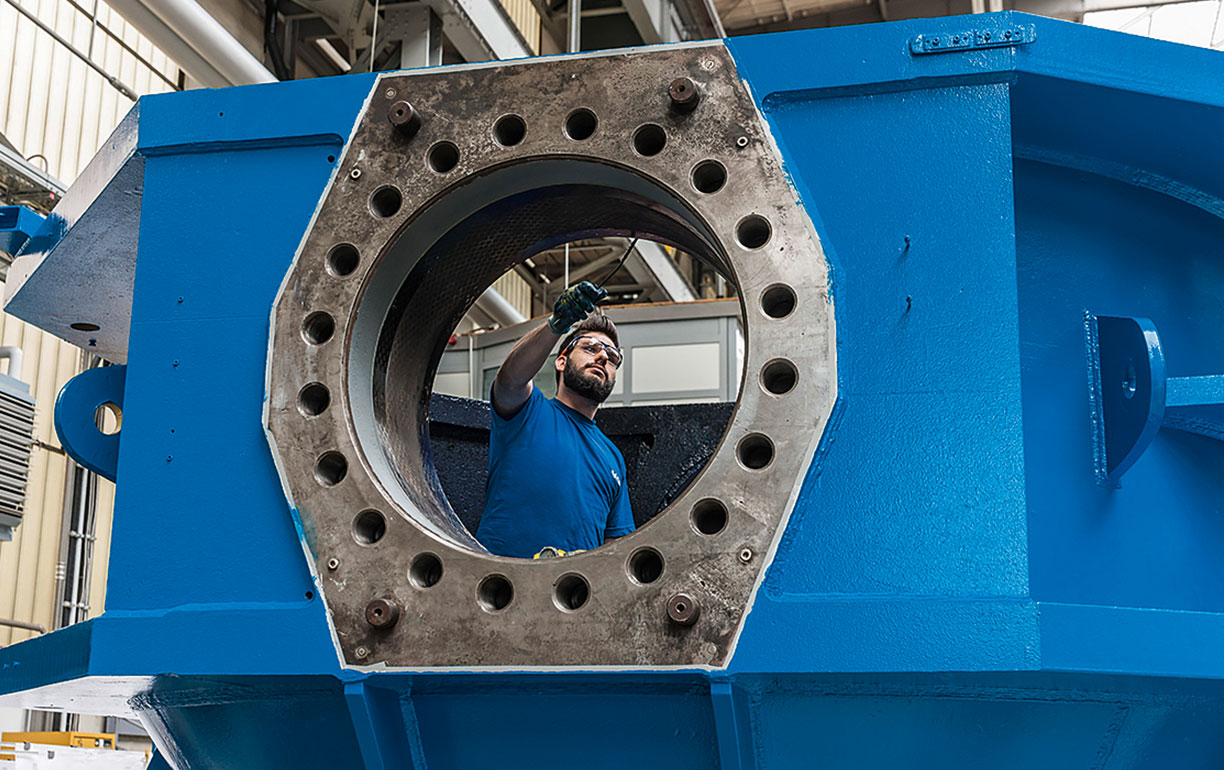

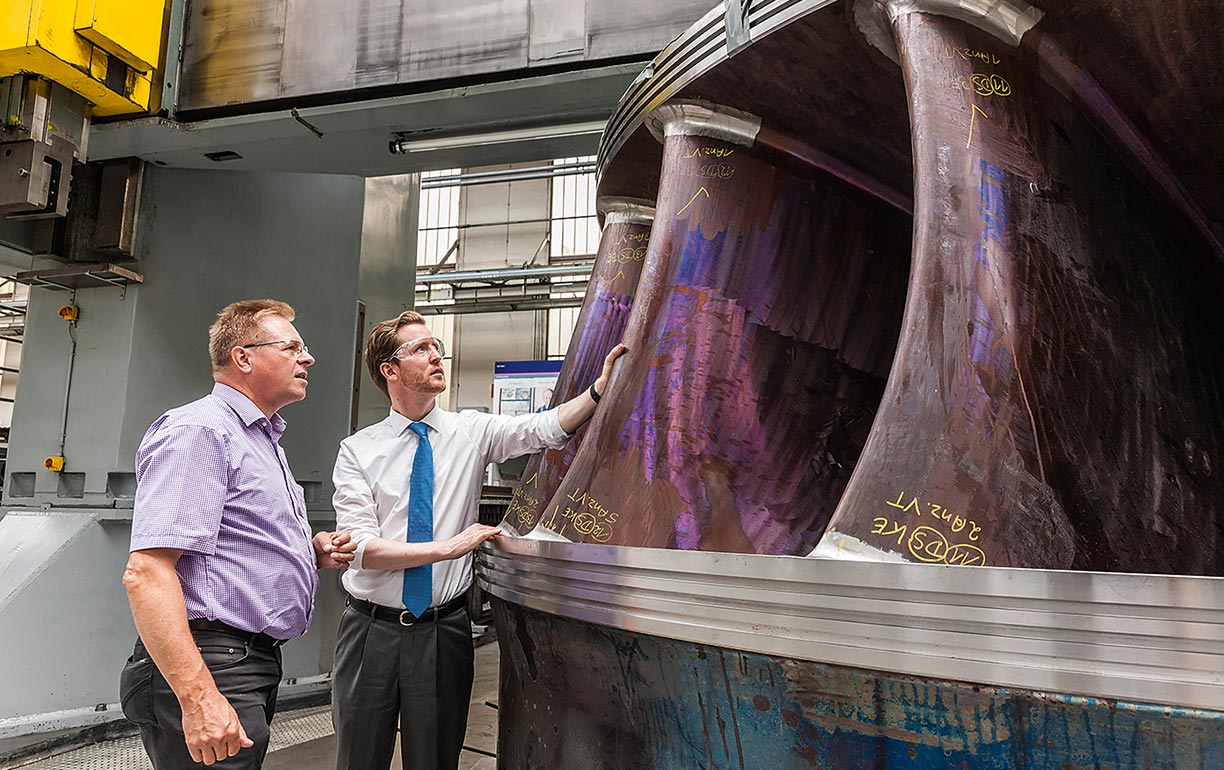

Two Voith plants are already installed in Angola and the third is on the verge of being delivered. In its 120-ton stator, the fixed part of a generator, two men are meeting each other who share a passion for technology: Georg Knöbel, Head of Turbine Production at Voith group headquarters in Heidenheim and Alexis von Hoensbroech, Lufthansa Cargo Board Member. “We work here for up to four months on a generator like this with around 20 co-workers,” explains Knöbel. “Almost 25 tons of copper are used in constructing the coils – approximately as much as in three million smartphones.”

Alexis von Hoensbroech listens attentively to the comments of the turbine specialist. With a speed of 180.5 revolutions per minute, a giant electromagnet in the stator will later whirr into motion and generate 178 megawatts of output,” continues Knöbel. The life span of the plant is more than 25 years.

Synonymous with quality.

The name Voith has stood for quality – for over 148 years. With more than 39,000 co-workers and revenues of more than five billion euros, Voith is one of Europe’s major family-run companies. The business is concentrated into four divisions: Voith Hydro is a fullservice supplier equipping hydroelectric plants of all sizes.

Voith Industrial Services is one of the leading suppliers of technical services for various key industries such as automotive, aerospace, energy, oil and gas as well as chemicals and petrochemicals. Voith Paper is a systems supplier for the international paper industry that covers the entire paper production process. Among other things, Voith Turbo produces powerful drive and braking systems, for example for streetcars or express trains.“Whenever you switch on the reading lamp in an intercity express to read a newspaper, often all four Voith sub-groups are involved,” explains Georg Knöbel, proud of the diversity of the Group.

Rapid availability puts higher costs into perspective.

The company is a pioneer in most of the technologies on offer. The reason: “The high quality and production standards that have been established by Voith in Germany apply to all Voith sites throughout the world. We are an internationally positioned technology Group that is represented by branches in more than 50 countries,” says Andreas Sedlatschek. The 44 year-old is responsible for the Groupwide purchasing of transport services and for setting up global supply chains. “Voith produces on a global scale. To promote smooth and rapid collaboration between the various Voith manufacturing facilities, suppliers and customers, sophisticated logistics chains are naturally required,“ adds Andreas Sedlatschek.

It is precisely here that Lufthansa Cargo comes into play. “Whether it’s poles for generators or especially valuable components for regulators, our consignments have to get reliably and quickly to Voith sites or customers at the other end of the world. Otherwise things get expensive. We’re able to make up for the higher transport costs thanks to more rapid availability.” Alexis von Hoensbroech nods: “Even more expensive than airfreight is no airfreight.” Whether it’s components for paper machines, couplings for express trains or large and heavy parts for hydroelectric power stations – Lufthansa Cargo sees to it that Voith customers around the world receive the products they’ve ordered on time, securely and rapidly.

The airfreight tonnage transhipped each year by Voith amounts to several tens of thousands of tons. “Part of that flies with us,” explains Michael Butz, Account Manager Sales at Lufthansa Cargo in Stuttgart, who is responsible for Voith.Andreas Sedlatschek adds: “We rely on Lufthansa Cargo when it comes to spare parts logistics too.”

Here, both partners are jointly breaking new ground. “Shortly we will be offering a product with which the installer and the spare parts can travel together in one plane,” says Alexis von Hoensbroech. “It’s very clear: a spare part doesn’t work without an installer and an installer can’t work without the spare part. The logical consequence: both have to travel on one plane to guarantee they arrive at the same time.

”It is this closeness above all that Voith appreciates in its preferred carrier. “Lufthansa Cargo is very broadly-based and reliable. The company has a powerful global network and has dedicated contacts in all areas who can respond flexibly to customer requirements,” explains Sedlatschek, looking over at Michael Butz. The Voith logistics professional sees scope for improvement in the networking of the technologies used for different types of traffic.

“In future we must coordinate communication better between all those involved in the supply chain, step it up and make it more transparent. This will deliver greater value for everyone. Here too, though, I can see that we are on the right track together with our partner Lufthansa Cargo.”

Alexis von Hoensbroech agrees: “In reality a number of challenges still await us in this area. However, with Voith we speak the same language. When we talk about quality or reliability, for example, we mean exactly the same thing. That’s why I’m certain that when it comes to the subject of more efficient networking we will make progress with Voith.”

"What impressed me."

What particularly fascinated me during my visit here to group headquarters in Heidenheim was the all-pervading passion with which Voith’s co-workers deliver the highest levels of technological performance for their customers. No matter whether in the turbine hall, for paper machines or for ship propulsion systems: the hearts of all those who work at Voith beat for the customer.

”What we have in common.“

Voith and Lufthansa Cargo are united by a very similar corporate culture: an international approach and the same appreciation of quality that deserves the label ‘Made in Germany’.”

Photos:

Bernhard Huber, Jürgen Mai/Lufthansa Cargo