Logistics flowing like water

Not everyone takes it for granted to open the tap and let fresh water flow. The inhabitants of the state of Nuevo Léon in Mexico also have to struggle with water shortages. In the summer of 2022, the region was hit by a severe drought. Some of the dams that supply water to the region of 5.3 million people had reached less than 1% capacity. Water consumption by private households was severely limited and water trucks drove to the hardest-hit areas to distribute water to residents, but civil unrest was already developing over the distribution of the precious wet.

You can watch on this project on the YouTube channel of Lufthansa Cargo: https://youtu.be/0FVh6MgnBsE

|

The government had to find a solution to this existential challenge. In July 2022, the government of Nuevo Leon announced the start of the "El Cuchillo II" construction project. To be completed in a record time of less than a year, the project will then bring 5,000 liters of water per second over 110 kilometers from the small Mexican town of China to the metropolis of Monterrey. |

The ten construction companies involved, three piping companies, the steel companies and also the pump manufacturer "Ruhrpumpen" all come from the state of Nuevo Leon.

|

"Ruhrpumpen" with its headquarters in Monterrey does not sound very Mexican at first. But it conceals an impressive history of Mexican entrepreneurship. In 1997, Ruhrpumpen from Witten was bought by Cesar A. Elizondo Villarreal, who was the first Mexican entrepreneur ever to invest in a German industrial company.

|

Today, the pump manufacturer has production facilities in ten countries around the globe. The close cooperation between Mexico and Germany still exists. Jose Luis Martinez Gonzalez, Global Logistics Director at Ruhrpumpen, also appreciates the close cooperation: "We come from Monterrey, the industrial heart of Mexico, with a well-known strong work ethic. |

Our colleagues in Germany have first-class technical experience. Side by side, we join forces and have been able to create a strong conglomerate that allows us to grow together, learn from each other and build a strong partnership to spread in different countries, with one mission: to be the supplier of choice for our customers."

|

"The ease of doing business with us is what defines our company. We're a family-owned and -run business that makes decisions quickly and always puts our customers' needs first."

Jose Luis Martinez Gonzalez, Global Logistics Director, Ruhrpumpen

|

Martinez Gonzalez knows that Ruhrpumpen was not only chosen for its proximity: "Time is of the essence in this project. The biggest challenge is planning and allocating all resources to the day in order to complete such an important project in record time. Our corporate culture is also an advantage here: we make decisions within days, while others take months. We have plants in the same locations as our competitors and similar products and manufacturing costs, but what differentiates us is our flexibility and the speed with which we work." The valves of the required pumps for the construction of the dam are manufactured in Germany. The pump manufacturer Ruhrpumpen chose the German forwarder H.J. Schryver & Co for the transport services, which they already knew from other projects. The logistics manager of Ruhrpumpen sums up the selection process: "We were looking for motivated and expert partners who understand the meaning of this project and who would enable us to transport the required components from the other side of the world within a few days. |

A delay on our side could have an impact on several tasks during construction and a very sophisticated plan would be thrown into disarray." Hamburg-based logistics company Schryver also has a close relationship with South America. "We are represented in nine countries in Latin America with the Schryver brand," says Carsten Schryver, Managing Partner of the company. "Hamburg was and is a gateway to the world. And Hamburg's connection with Latin America has brought together tradesmen and women and companies for centuries. This has given rise to business opportunities, then small outposts of Schryver, and now independent organizations with a total of more than 300 employees." Schryver serves very diverse markets in this region. In Brazil and Mexico, they operate in industrially developed countries. In Ecuador and Peru, they often work with large suppliers of mining products or food manufacturers.

|

"We are very broadly positioned and, of course, particularly enjoy large logistics projects with producer’s goods. The more complicated the better. And that doesn't necessarily always have to be a large volume," says Carsten Schryver, Managing Partner of H.J. Schryver & Co. Schryver loves the challenge of logistics projects. His heart's project was the construction of a CO₂ -neutral thermo-solar power plant on the Galapagos Islands in the Pacific, which Schryver was able to support logistically.

|

The construction of the dam in Nuevo Léon is primarily about the time factor. Reloading the shipment is out of the question in view of the urgency. Added to this were other uncertainties such as the move from freighters from the capital's MEX airport to the NLU airport requested by the Mexican government. "We need planning capability and personal accessibility of contact persons in case of problems. |

This is given for us both here in Germany and in Mexico with Lufthansa Cargo. Due to the size of the shipments, only the transport by freighters is an option. With the direct freighter flight from Frankfurt to Mexico six times a week, both the capacities and the conditions are right," reports Schryver.

|

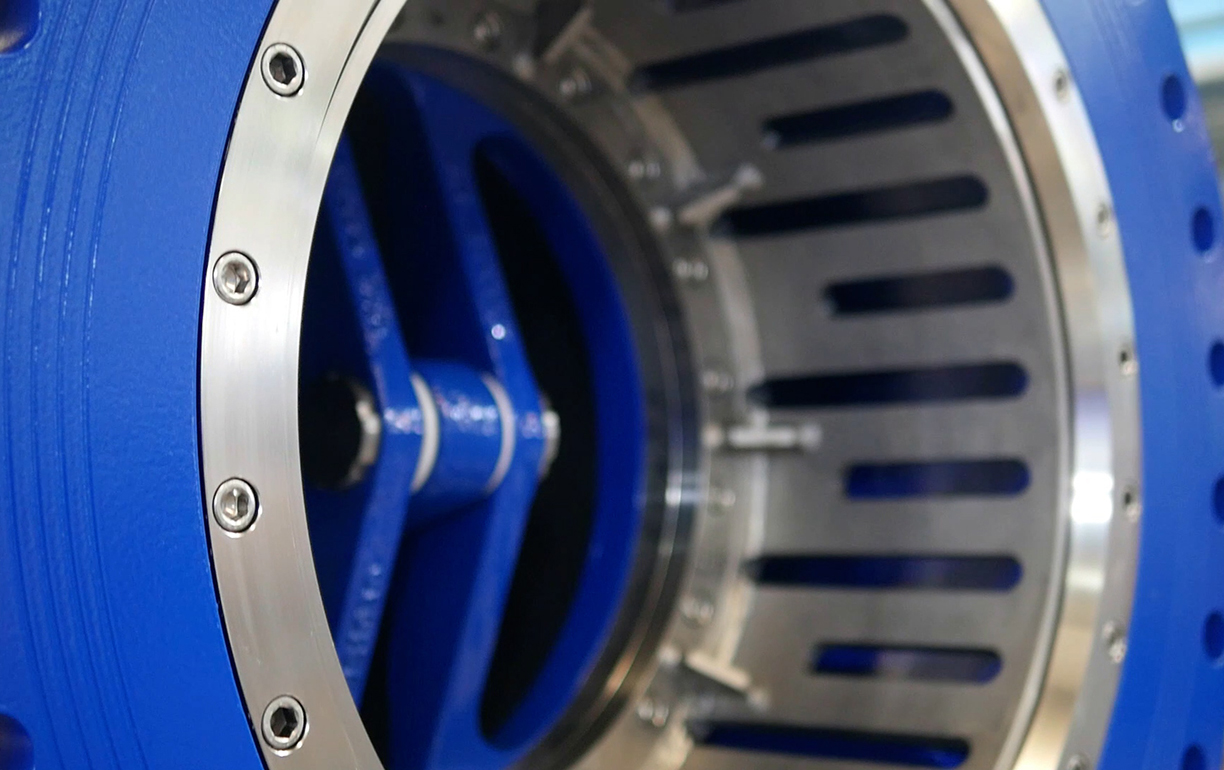

"In total, we have transported 175 tons in 14 shipments for the project so far. The largest shipment was 23 tons," says Gunnar Strauß, Key Account Manager for Schryver on the Lufthansa Cargo side. Even though the pumps are very large at 4.50 x 2.20 x 2.70m and the corresponding valves, the size is not a challenge for our freighters in this case.

|

However, the project coincided exactly with the changeover from Aeropuerto Internacional de la Ciudad de México (MEX) to the new Felipe Ángeles International Airport (NLU). The team in Mexico led by Frank Nozinsky, Head of Sales & Handling Mexico, Colombia, Ecuador, Central America and Caribbean at Lufthansa Cargo, has achieved an incredible accomplishment. In less than three months, they were able to open a new station at an airport that was basically not in operation at all, including opening a branch, introducing station and handling processes, starting ramp services, fueling and all the related organization and communication. |

On July 7, the last Lufthansa Cargo freighter flight landed in MEX, and on July 8, the first B777F of the cargo crane, with flight number LH8220, landed in NLU. On board both aircraft was equipment for the El Cuchillo II Dam pumps.

|

"This project is a particularly fine example of how to support local companies and yet promote global cooperation," sums up Frank Nozinsky, Head of Sales & Handling Mexico, Colombia, Ecuador, Central America and Caribbean at Lufthansa Cargo.

Arrived and installed in Mexico, the pumps deliver top performance. Many years of experience go into the design and manufacture of the pumps, which operate under continuous load. One of the "ZW Horizontal Split Case Pumps" can reach up to 9000 cubic meters per hour and a head of 340m with 14mt. A total of 30 pumps of this type are planned in the construction project.

"We have already installed more than 60,000 pumping solutions in more than 90 countries and always give our best. Providing millions of families in our hometown with water in the long term until 2050 fills us with special pride this time!" tells family man Jose Luis Martinez Gonzalez. "And I can say that the logistics are a resounding success. The cooperation with Schryver and Lufthansa Cargo is an absolute win. Now, all of us can hardly wait for the first water to flow through the dam to the families in Monterrey."