Pharma ninjas.

In the past, Kōka was home to legendary ninjas who produced herbal medicines. Today, in the small Japanese city Bayer produces innovative drugs for the huge domestic market. The raw materials are supplied by airfreight.

|

A small town on the south west of Japan’s largest island, Honshu: a museum honouring legendary ninja warriors, lush vegetation with vast woodlands, plenty of rivers and almost 90,000 people spread over several locations. In the rural community of Kōka, people are linked to Japan’s major metropolitan areas in that they receive first-class treatment in the event of illness. Japan’s public health system is seen as one of the most highly developed worldwide. Strategic Importance Whether young or old: the city of Kōka has played a major role in treating the Japanese population for hundreds of years. In times past, the region’s ninjas were skilled in preparing medicines based on herbs in addition to martial arts. Today, Kōka is home to the Supply Center Shiga, the plant of Bayer Yakuhin, subsidiary of the German global company Bayer, named after the surrounding prefecture.

|

Katayama, Plant Head and Head of Product Supply Japan of Bayer Yakuhin. After the US, Japan’s pharmaceutical market is the second largest worldwide in relation to drug products originally developed and marketed by pharmaceutical companies. |

Standing united: Dr. Hirohito Katayama, Head of Product Supply Japan at Bayer Yakuhin (far left), with Yoshihiro Yamamoto (Lufthansa Cargo) and the Bayer Supply Chain Manager Peter G. Meyer (Asia Pacific) and Nobuyuki Hirono (Japan).

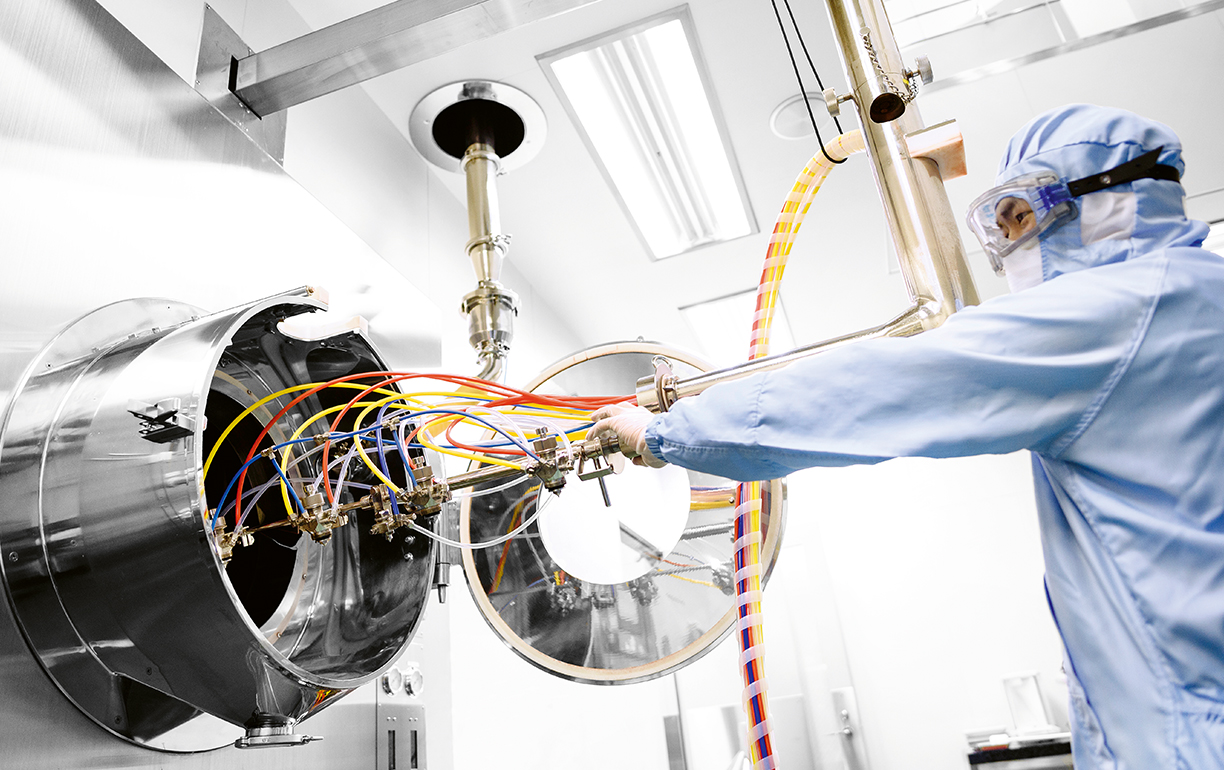

Control: drug freight is often transported in a temperaturecontrolled environment to preserve drug efficacy. Prime importance is attached to handling.

Push: Unicooler containers, used by Lufthansa Cargo as part of the product Cool/td, enable freight temperatures to be managed between minus 20 and plus 30 degrees Celsius.

|

A third product, a granular powder filled in small bags, is similarly geared towards people with swallowing difficulties. Furthermore, Bayer Yakuhin has introduced tablets with a different time release of the active ingredients so that patients need only take one per day instead of two units. Smooth Product Replenishment To avoid the replenishment of products from the Supply Center Shiga grinding to a halt, a Lufthansa Boeing 747-400 lands at Kansai International Airport – IATA abbreviation: KIX – just outside Osaka, on a weekday morning punctually at 8.40 a.m. In the belly of the passenger jet from Frankfurt are half a dozen Unicooler containers for the temperaturemanaged transport. The container displays show an internal temperature of five degrees Celsius. “We transport goods for Bayer Yakuhin to here every week,” says Yoshihiro Yamamoto, Regional Manager Western Japan of Lufthansa Cargo. The manufacturer has been placing its trust in Lufthansa Cargo since 2008.

|

says Hirohito Katayama. The goods are flown in from various European countries. For example, the Unicooler containers, which have arrived in the Boeing 747-400 – flight number LH740 – have already completed a feeder flight from Milan to Frankfurt. Bayer finished products for the Japanese market also regularly land on board Lufthansa machines at KIX Airport. However, they are not supplied to the plant in Kōka, but rather are transported directly to the manufacturer’s distribution centre in Osaka. |

Pharmaceutical Product Handling in KIX

Lufthansa Cargo has been providing ultra-fast handling services for Bayer Yakuhin at Kansai International Airport (KIX) just outside Osaka since 2011. A customs agent clarifies the necessary formalities regarding the consignments that arrive each week on board a Boeing 747-400, stored in Unicooler containers, in just 70 minutes. Meanwhile, the goods, which are as valuable as they are sensitive, are stored in Lufthansa Cargo’s cooled import warehouse to protect them from exposure to the sun. Excellent infrastructure is in place via the KIX Medica Pharmaceutical Warehouse for the breakdown and interim storage until collection by the truck forwarding agent.

Photos:

Ben Weller