It's in!

The launch of the Airbus A350 is a milestone in passenger aviation. And Lufthansa Cargo will be part of the global service infrastructure: via a Boeing 777F, the A350’s huge engines quickly reach any destination.

|

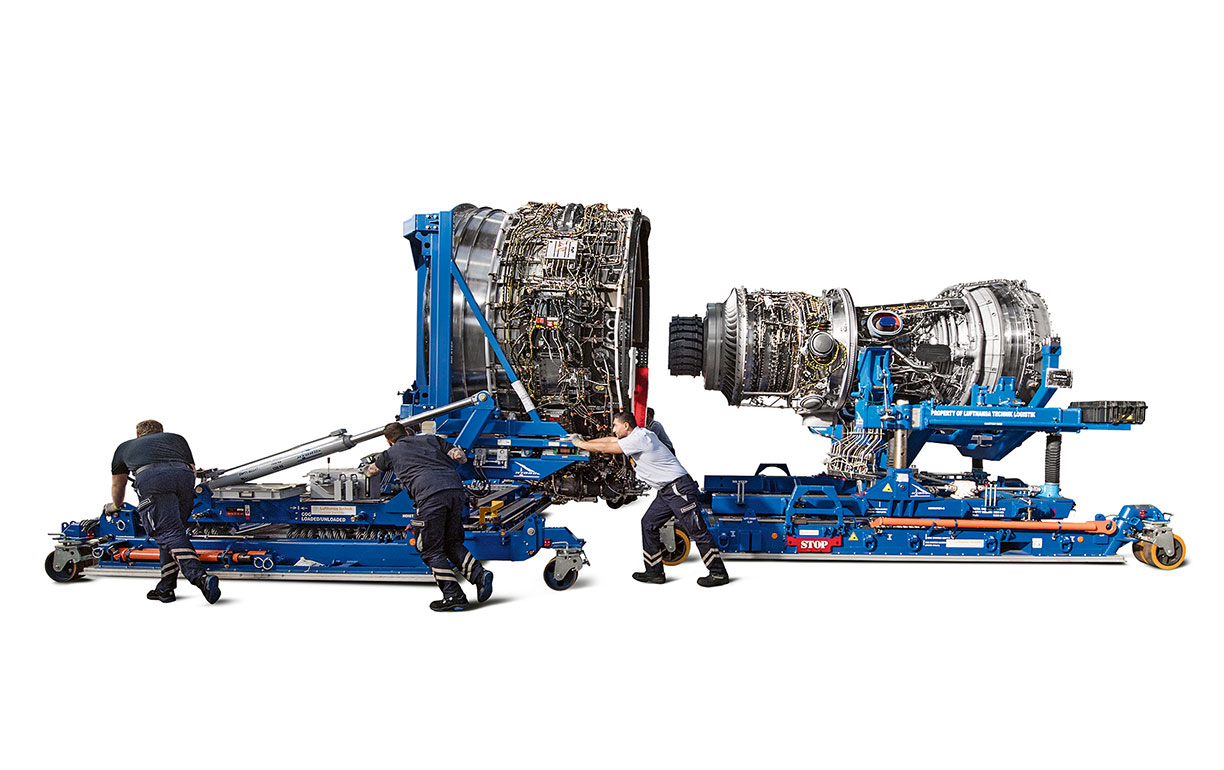

The transport stand containing the huge engine module is slowly pushed through the cargo door of the Boeing 777F. The area between the packed fan module and the freighter’s loading area ceiling spans just a few centimeters but is important for Lufthansa Cargo. In conjunction with Lufthansa Technology, Lufthansa Cargo has successfully trialed a new transport stand from Rolls-Royce. The manufacturer of the Trent XWB engines for the Airbus A350 pulled off a quantum leap in the process: flying one of the huge aggregates – dismantled inindividual modules – in a Boeing 777F. In the assembled condition alone, each Trent XWB weighs seven tons, has a fan diameter and therefore a height and breadth of three meters and a total length of five meters. A transport stand is required at all times, adding to the weight and dimensions. That is too big even for the largest freight door of the Lufthansa Cargo B777F.

|

As a result, the engine can actually only be flown via special freighters such as the Antonov An-124, the Airbus Beluga or a Boeing C-17. This is a considerable disadvantage, in particular in the event that an Aircraft on Ground (AOG) is reported due to engine problems. Three steps were necessary to create the prerequisites for such a Triple Seven assignment. First of all, Rolls-Royce developed a new type of transport stand on which the engine can be stored and divided into two large modules to fit in the B777F. In a second step, the team made up of employees fromLufthansa Cargo, Lufthansa Technik and Lufthansa Technik Logistik Services trialed the load with an original engine. Rolls-Royce had made it available especially for the test load. To that end, the employees initially separated the fan from the core engine and removed the spinner and fan blades. The two modules could then be independently moved and loaded on the fan case stand and the core split engine stand.

|

New Lashing Concept

The third step involved reviewing and releasing the lashing concept for the transport stand in the freight area of the B777F. So-called supplementary procedures for the Weight & Balance Manual of the B777F specify how freight items, which cannot be secured via the existing strapping system because of their size, are to be loaded and lashed. As in the case of the GE90 engines of the Triple Seven, which are almost equal in size and for which corresponding supplementary procedures have long been in place, Lufthansa Cargo’s own loading and lashing plan is used that specifies how many straps need to be applied to secure the two transport stands and the points in the freight area where they need to be placed.

Irrespective of the huge dimensions, the Trent XWB fits in the Lufthansa Cargo B777F. And it is a little ironic that it is a Boeing freighter that secures the A350’s triumph. With a loading concept ideally geared towards the freight and freighter, Lufthansa Cargo is now ready for the A350 era.

A large part of the success: dividing the Trent XWB engine creates the prerequisites for loading in the B777F. Lufthansa Cargo can therefore provide worldwide service for the A350.

Separating engine components is a highly complex matter. Rolls-Royce technicians therefore instructed the Lufthansa employees on how the components need to be dismantled and reassembled.

Focus: The A350-900

The A350-900 is the world’s most modern and environmentally-friendly long-haul aircraft. It consumes 25 percent less kerosene and creates 25 percent fewer emissions than comparable models. Its noise footprint is up to 50 percent smaller. At the core of the twin-jet concept are two Trent XWB-84 type engines, each with thrust of 374.5 kilonewtons and a weight of 7,277 kilograms. In December 2016, the first of the ten Lufthansa planes was based in Munich. Initial destinations will be Delhi and Boston. The aircraft has room for 293 passengers: 48 guests in Business Class, 21 in Premium Economy and 224 in Economy Class.